SysTherm® ECO Komponente A + B

The polyurethane innovation for perfect earmolds.

5:1 bottle version.

5:1 bottle version.

Price on request

Product number:

A4020251 & A4020253

Product information

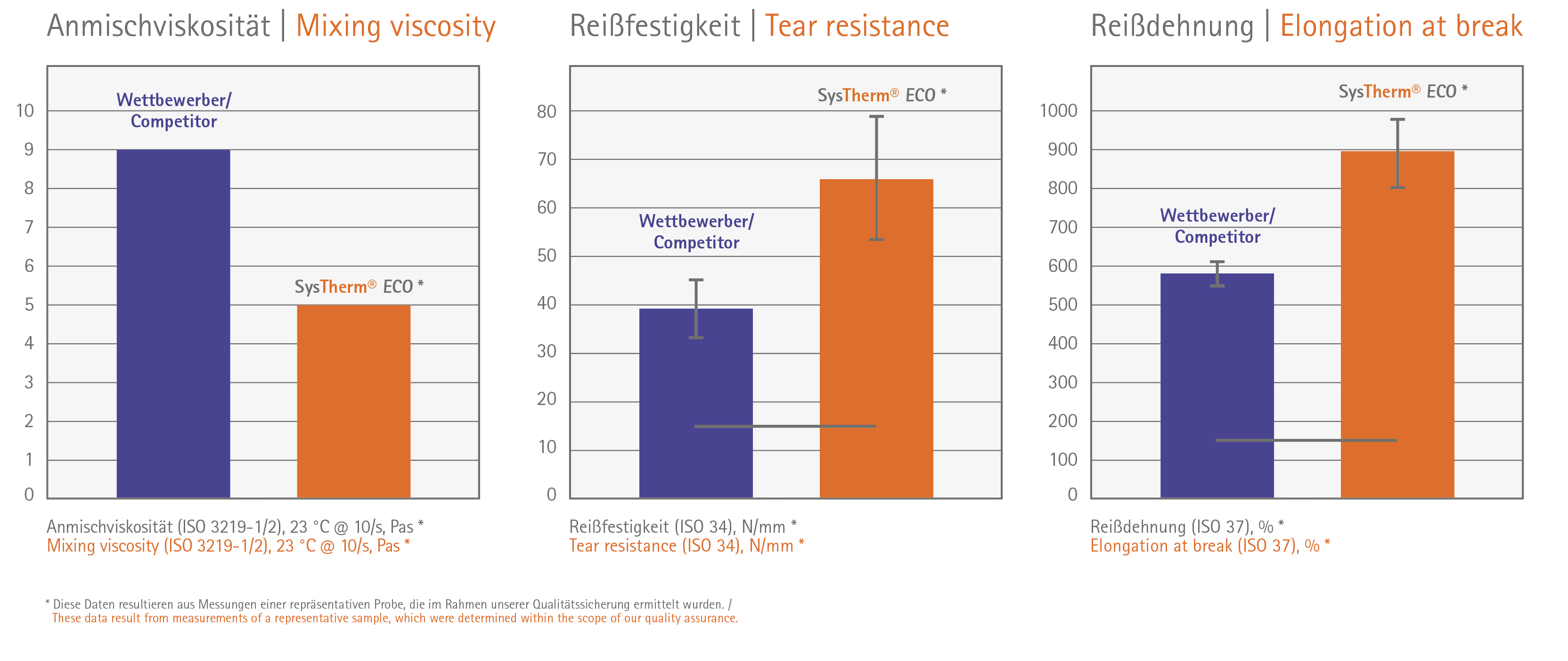

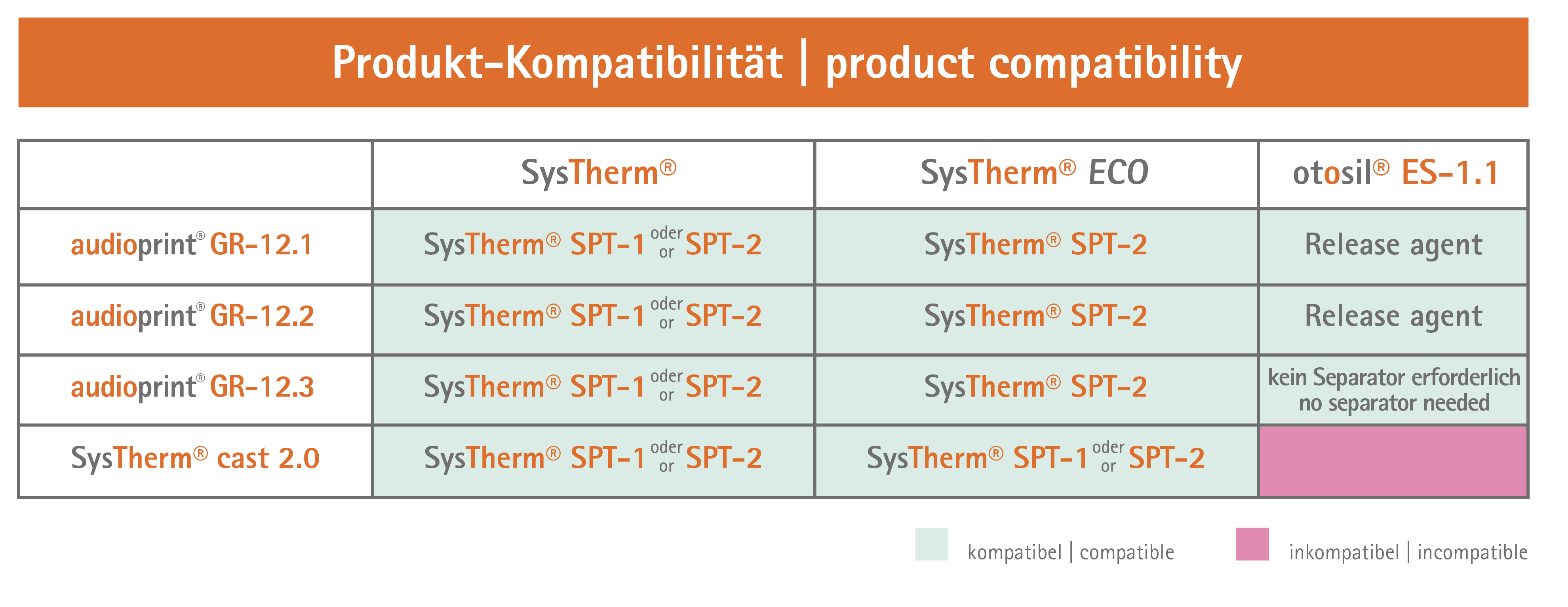

With the 2-component material SysTherm® ECO, we offer you an economical alternative in the field of thermoflexible PU materials to open up further price-sensitive applications. The 5:1 material is available as a casting resin and offers a thermo effect (see Fig. 15) and moisture transport comparable to the state of the art. This has no influence on the mechanical and physical properties, as shown in Figs. 18-21. SysTherm® ECO also contains no free Isocyanates in monomer form and thus meets the highest occupational safety requirements for the manufacture of thermoflexible earmolds. In addition, the material's exceptionally long processing time gives you a high degree of flexibility in the design of your production processes.

Advantages:

- bottle version (5:1)

- lowest mixing viscosity in its class

- outstanding processing time (1h at 23 °C)

- linear thermal effect

- high UV stability

- excellent transparency

- best mechanical properties