SysTherm® cast 2.0

Product information

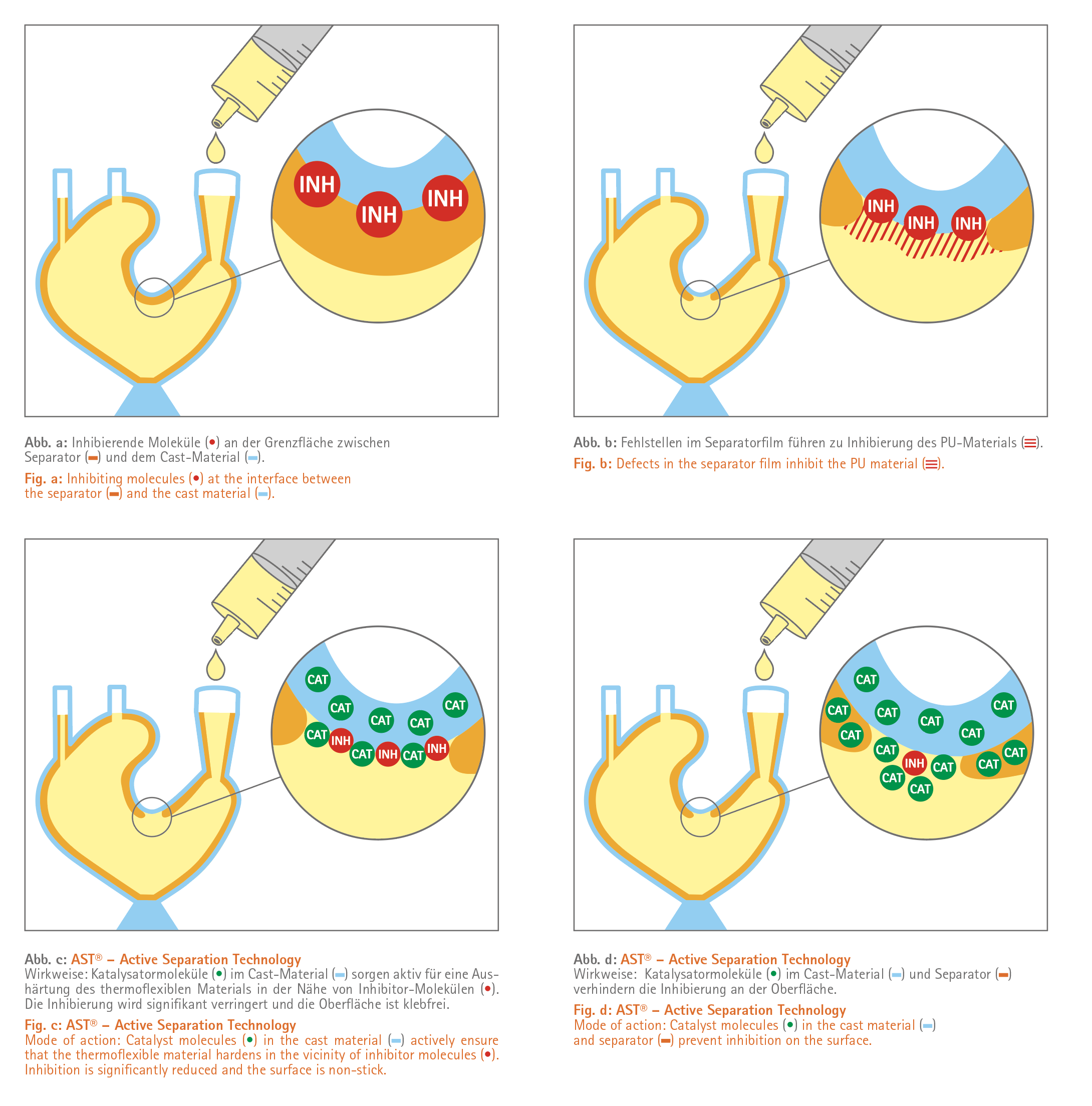

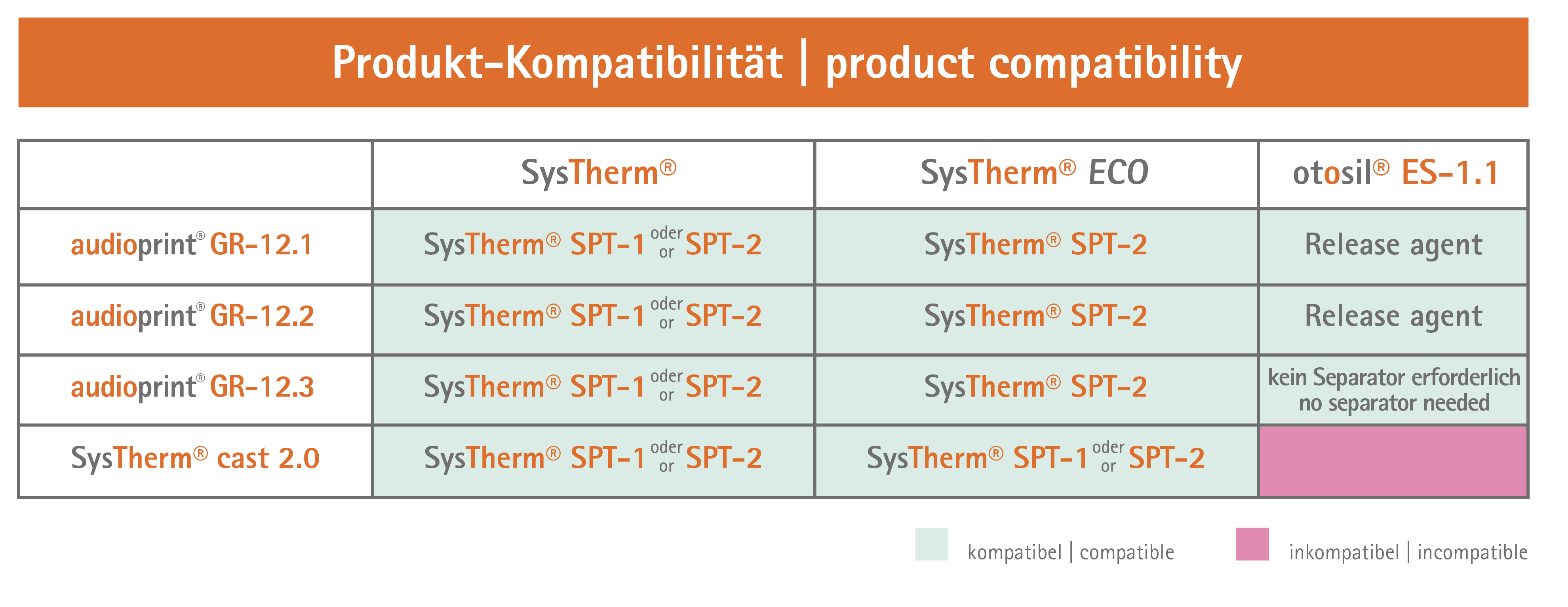

With SysTherm® cast 2.0, we are introducing a world first: a cast material for 3D printing that actively supports the curing of thermoflexible casting materials in the cast mold. It is known from daily practice that the catalyst of PU materials can be inhibited during the manufacturing process by, for example, chemical by-products, moisture, or contaminants on/in the casting mold. This inhibition occurs at the interface between the casting material and the cast mold and subsequently leads to incompletely cured areas or sticky surfaces. For this reason, film-forming separators such as SysTherm® SPT-1 are used. (Fig. a) However, depending on the internal geometry of the casting mold, the separator film can tear at sharp edges/bends, causing the above-mentioned inhibition to occur. (Abb. b) This is where pro3dure's Active Separation Technology (AST®) comes in. The resin used for the generative production of the cast molds also incorporates a catalyst for curing the casting material, which ensures perfect curing even at the interface (Fig. c). This results in significantly more robust and therefore more efficient casting processes. The innovative Active Separation Technology (AST®) can also be combined very effectively with the highly advanced SysTherm® SPT-2 separator, which is also equipped with AST® (Fig. d).

Advantages:

- prevents sticky surfaces by actively supporting polymerization

- easy to peel, without sharp edges

- no nitrogen atmosphere required

- high transparency

- no discolouration during post-curing